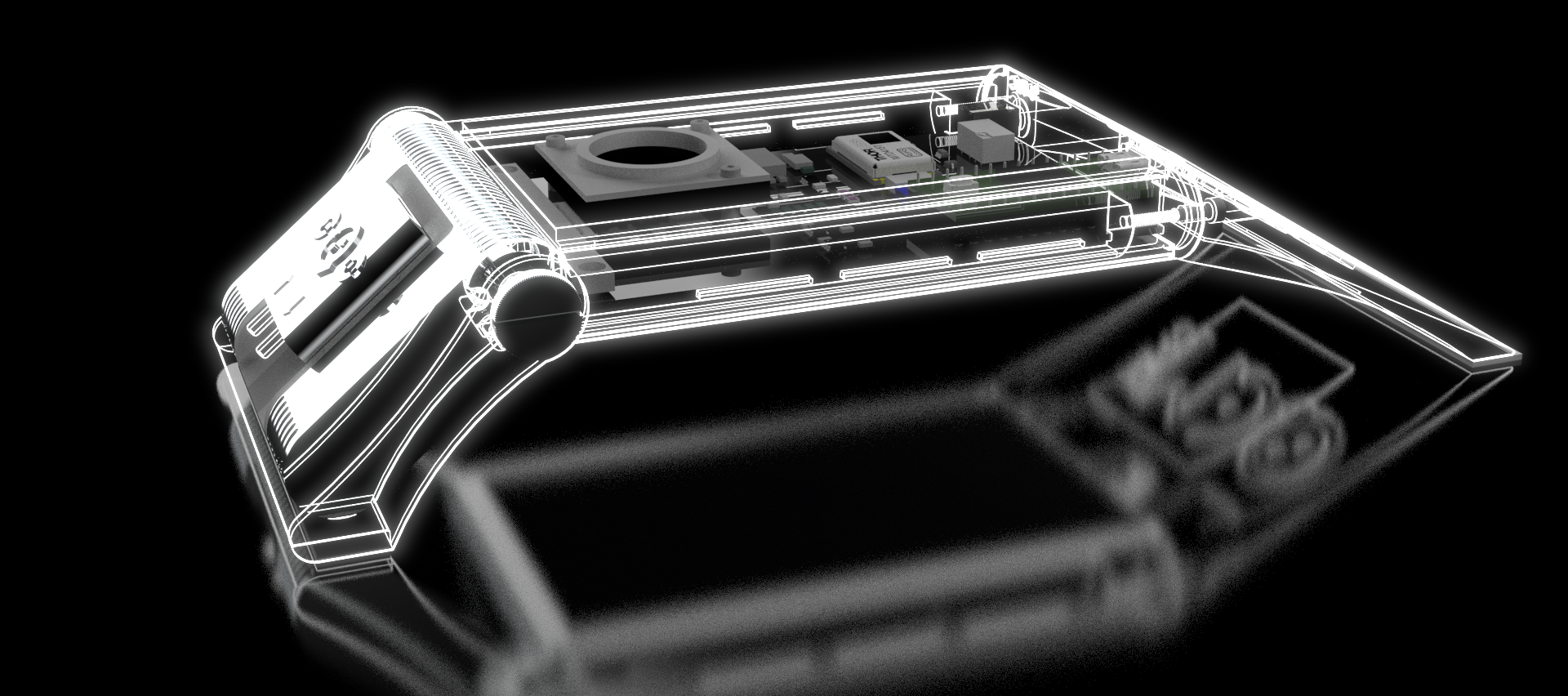

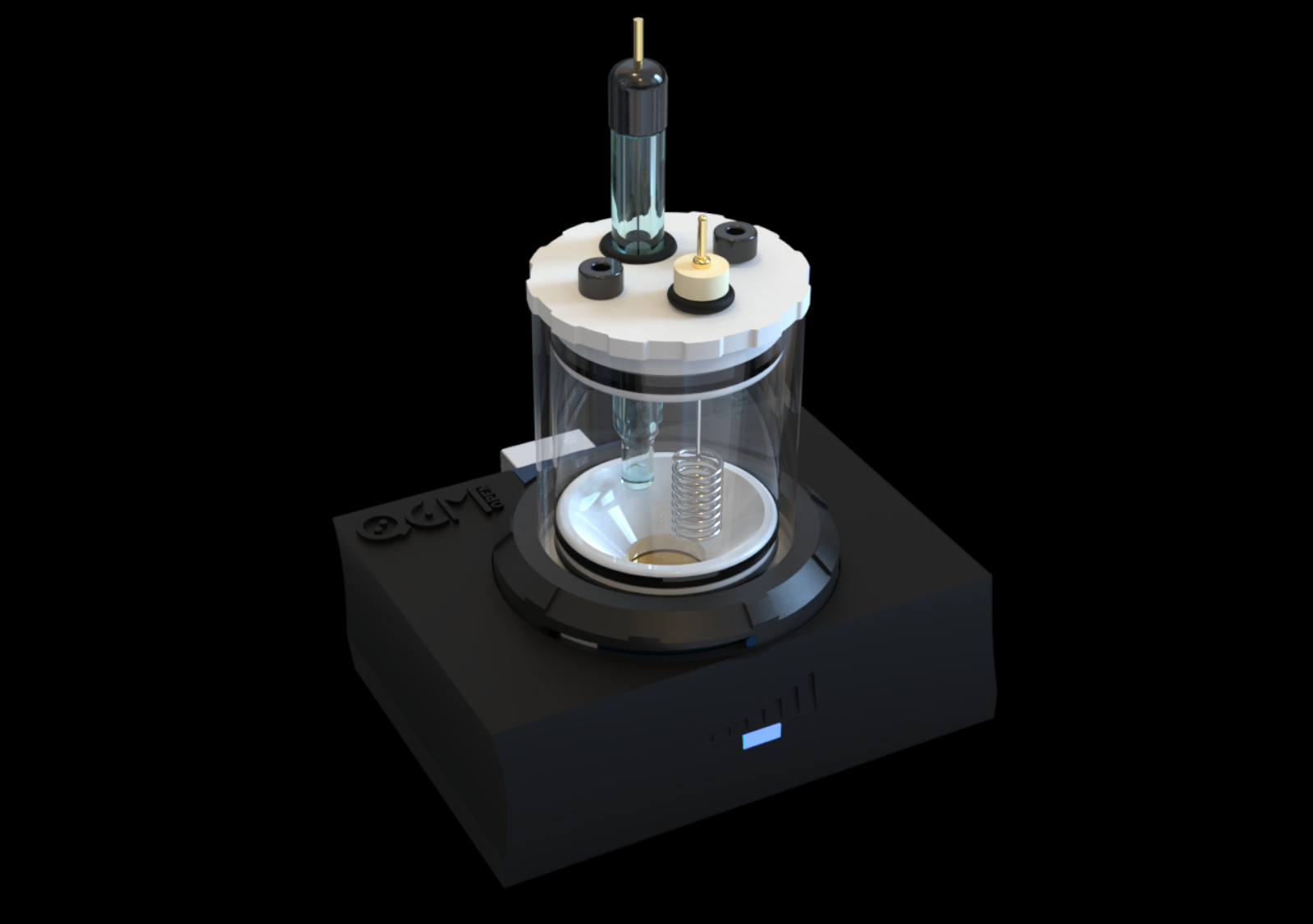

openQCM Next Design: Mechanical Component and Material Selection for Improved Thermal Performance

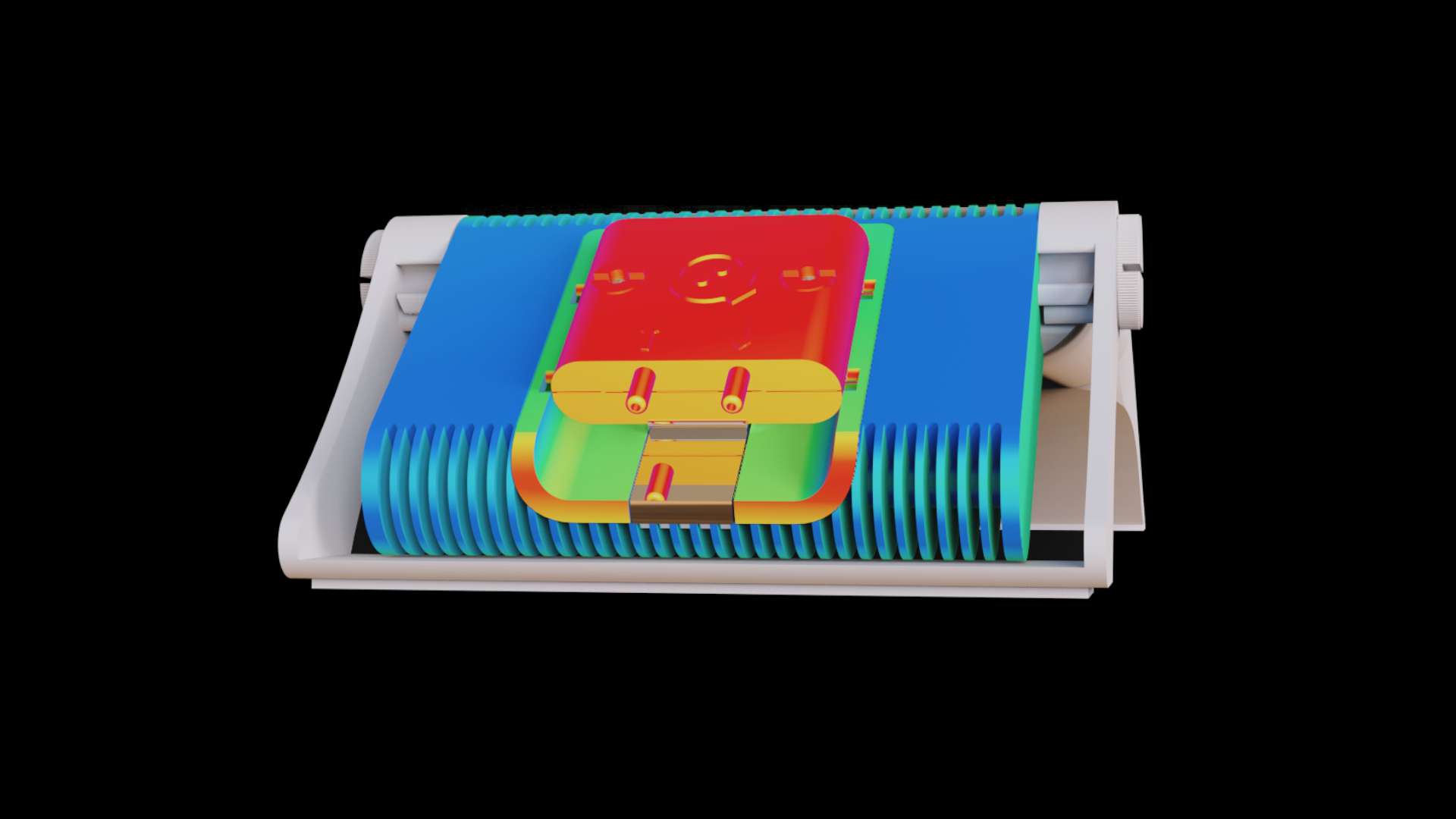

OpenQCM NEXT was developed with the intention of maximizing thermal dissipation. The innovative design optimizes the device for research applications.

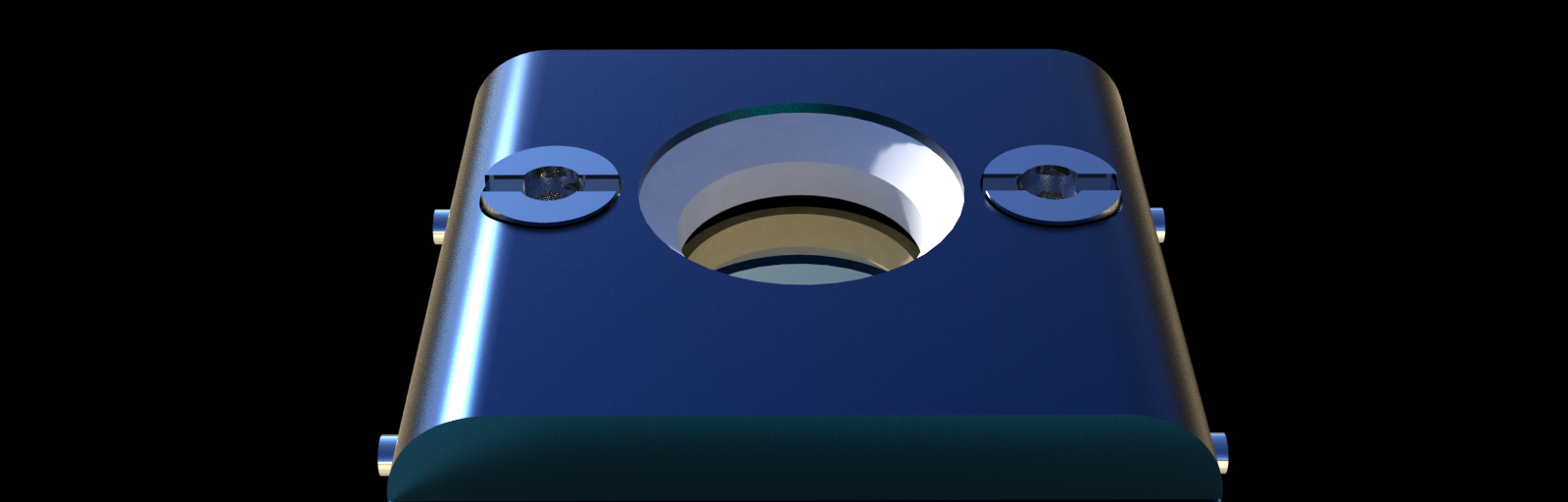

The design of openQCM NEXT is the result of valuable feedback gathered from the scientific community. The distinctive bridge design aims to optimize thermal dissipation and minimize electrical interferences. The sensor module has been upgraded with a custom heat sink featuring an integrated PTFE slot that houses the fluidic module. The fluidic module serves as the primary holder for the quartz sensors and it is desgined also as a multi-purpose accessory.